The year 2025 has solidified a new reality for global supply chains: complexity and disruption are no longer exceptions, but the norm. Businesses are grappling with a relentless barrage of challenges, from geopolitical volatility to soaring customer expectations. Traditional management tools and fragmented systems are proving inadequate, leaving companies vulnerable and inefficient. The path forward requires a paradigm shift—a move toward intelligent, integrated, and predictive operations.

This article explores the critical pain points defining the modern supply chain and reveals how a unified, all-in-one AI workspace is emerging as the definitive solution to not only survive but thrive in this new era.

- Chapter 1: The Unprecedented Challenges of the 2025 Supply Chain Landscape

- Chapter 2: The AI Revolution in Supply Chain Management

- Chapter 3: Core Capabilities: How an AI Workspace Optimizes Supply Chain Functions

- Chapter 4: Advanced Applications: Generative AI and Digital Twins

- Chapter 5: Democratizing Data: The AI Workspace for Every Stakeholder

- Chapter 6: Getting Started with Your AI-Powered Supply Chain Transformation

- Take Control of Your Supply Chain’s Future

Chapter 1: The Unprecedented Challenges of the 2025 Supply Chain Landscape

The aftershocks of the early 2020s have reshaped the global trade environment into a landscape of permanent uncertainty. While the initial pandemic-driven chaos has subsided, it has been replaced by a new set of persistent and interconnected challenges. For supply chain leaders, navigating this environment feels like steering a supertanker through a perpetual storm.

1.1 Geopolitical and Regulatory Complexity

International politics have become a primary driver of supply chain disruption. Trade policies and tariffs can shift with little warning, creating immense uncertainty for businesses with global sourcing and distribution networks. In early 2025, for instance, discussions around new tariffs on major trading partners created significant planning headaches for U.S. importers. One industry report noted that nearly 20% of trade professionals cited international politics as their top strategic concern, a figure that has likely grown since.

This political volatility is compounded by an increasingly complex web of regulations. Professionals in the field express a strong need for “regulatory clarity,” as sweeping new rules regarding everything from low-value shipments to sustainability reporting are introduced. The lack of clear guidance on how these regulations will be tracked and enforced leaves businesses struggling to ensure compliance, risking costly penalties and delays.

1.2 Persistent Disruptions and Extreme Volatility

The concept of a “stable” supply chain has become a relic of the past. The industry continues to reel from a combination of factors that create constant volatility:

- Post-Pandemic Realignment: While many operations are back on track, the ripple effects of port congestion, manufacturing delays, and labor mobility issues from 2021-2022 continue to be felt.

- Climate Change Impact: Extreme weather events are no longer black swan events but a recurring business risk. Wildfires, hurricanes, and droughts disrupt transportation routes, damage infrastructure, and impact raw material availability. Experts warn that climate-related disruptions could cost the shipping industry billions annually.

- Infrastructure Bottlenecks: Key transit points, like the Panama Canal, have faced operational challenges due to environmental factors, causing significant delays and rerouting. Similarly, strains at land borders, such as between the U.S. and Mexico, have emerged as companies pursue near-shoring strategies, creating new chokepoints.

One analysis found that global supply chain disruptions in the previous year led companies to incur financial losses averaging around 8% of their annual revenues, a staggering figure that underscores the high stakes of operational failure.

1.3 The Widening Talent and Skills Gap

As supply chains become more complex and digitized, the skills required to manage them are evolving rapidly. Companies face a critical shortage of talent with expertise in global trade compliance, data analytics, and AI implementation. Many organizations are finding that their existing teams are not equipped to handle the new demands of a data-driven supply chain.

Experts emphasize that trade compliance is now a highly specialized, multidisciplinary profession with significant liability. The problem is that the field is often only recognized “when things go wrong.” This reactive approach has led to underinvestment in training and development. To bridge this gap, companies are increasingly turning to external consultants or investing heavily in automation, but the core challenge remains: finding and retaining people who can translate complex data into actionable strategy.

1.4 Soaring Costs and Economic Pressures

Managing costs has become a monumental task. Inflationary pressures drive up the cost of raw materials and components, while volatile energy prices impact transportation expenses. Escalating shipping costs, exacerbated by climate-related disruptions and geopolitical tensions, add another layer of financial strain. Businesses are caught in a difficult position, trying to absorb these rising costs without passing them all on to consumers in an uncertain economic climate where consumer spending could slow.

1.5 The Customer-Centricity Imperative

While battling internal and external pressures, companies must also meet ever-increasing customer expectations. The modern consumer demands more than just a product; they expect a seamless experience. This includes:

- Speed and Reliability: Fast, predictable delivery is no longer a premium feature but a baseline expectation.

- Radical Transparency: Customers want to track their orders in real-time, from the warehouse to their doorstep. They are also increasingly concerned with the ethical and sustainable origins of their products, demanding transparency into the entire supply chain.

- Personalization: A customer-centric supply chain must be agile enough to cater to individual needs, from customized products to flexible delivery options.

A recent survey by a leading research firm revealed that customer experience (CX) is one of the top three business priorities for supply chain organizations. However, many companies lack the metrics and systems to measure performance as the customer sees it, creating a disconnect between their operational goals and customer satisfaction.

The Core Dilemma: Businesses are being asked to become more agile, resilient, and transparent while simultaneously navigating unprecedented complexity, cost pressures, and talent shortages. The traditional, siloed approach to supply chain management is fundamentally broken. A new, integrated intelligence is required.

Chapter 2: The AI Revolution in Supply Chain Management

Faced with the overwhelming challenges of the modern era, supply chain leaders are turning to a transformative force: Artificial Intelligence. AI is no longer a futuristic concept discussed in academic papers; it is a practical, powerful tool being deployed today to bring order to the chaos. The adoption of AI is not just a trend—it is a seismic shift that is redefining the competitive landscape.

2.1 An Exploding Market and an Undeniable Trend

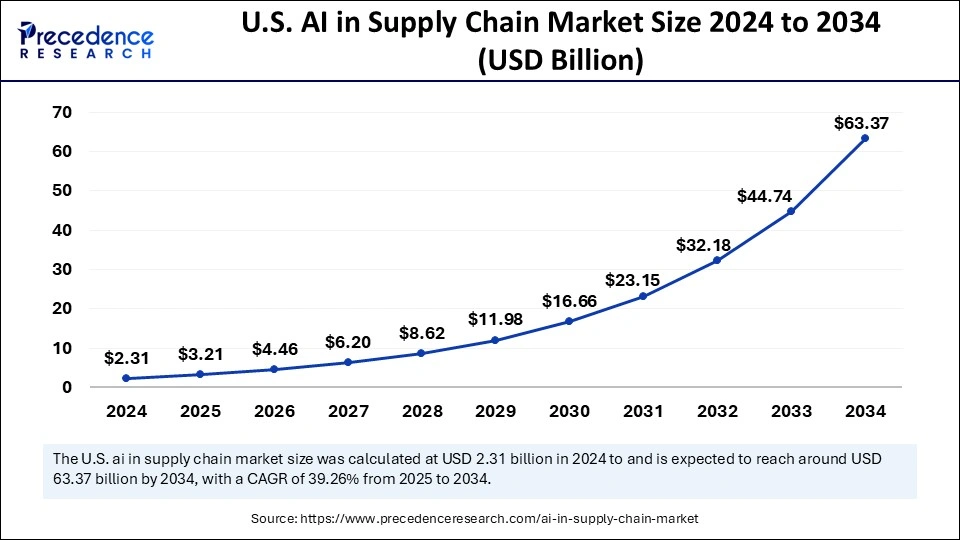

The growth of AI in the supply chain sector is nothing short of explosive. Market analyses consistently point to exponential expansion. The global AI in supply chain market, valued at approximately $7.15 billion in 2024, is projected to surge past $9.94 billion in 2025. The trajectory from there is even more stunning, with forecasts predicting the market will reach a colossal $192.51 billion by 2034, growing at a compound annual growth rate (CAGR) of around 39%.

North America has led this charge, driven by the early adoption of AI-driven logistics and a robust digital infrastructure. The U.S. market alone, which stood at $2.31 billion in 2024, is expected to skyrocket to over $63 billion by 2034. This massive investment signals a clear consensus in the industry: AI is the future of supply chain management.

2.2 Why AI is No Longer Optional

What is driving this rapid adoption? Simply put, AI provides the capabilities needed to address the very challenges outlined in the previous chapter. While traditional systems struggle with static data and manual processes, AI thrives on complexity and real-time information. A 2024 survey showed that an overwhelming 98% of executives have already embraced AI to transform at least one aspect of their supply chain management.

AI-powered systems can:

- Process Massive Datasets: Analyze structured and unstructured data from thousands of sources—including sales reports, social media feeds, weather forecasts, and GPS signals—to uncover patterns invisible to the human eye.

- Predict and Prescribe: Move beyond reactive problem-solving to predictive analytics. AI can forecast disruptions, recommend optimal inventory levels, and even automate decisions to prevent issues before they occur.

- Automate and Optimize: Handle repetitive, manual tasks with speed and accuracy, freeing up human professionals to focus on high-level strategy, innovation, and relationship management.

Early adopters are already reaping significant rewards, with some reporting cost reductions of over 30% in overall supply chain operations and similar enhancements in planning accuracy. In this environment, failing to invest in AI is no longer a strategic choice; it is a decision to fall behind.

2.3 The Rise of the All-in-One AI Workspace

However, deploying AI is not as simple as buying a single piece of software. The true power of AI is unlocked when its various capabilities are integrated into a cohesive, unified platform. A fragmented approach—using one tool for forecasting, another for logistics, and a third for risk analysis—simply recreates the data silos that plague traditional systems. This is where the concept of an all-in-one AI workspace comes in.

Imagine a central nervous system for your entire supply chain. A single, cloud-based platform that connects procurement, production, inventory, logistics, and customer service. This workspace doesn’t just store data; it actively analyzes it, providing real-time insights and intelligent recommendations to every stakeholder. It democratizes the power of AI, making sophisticated tools accessible not just to data scientists, but to planners, managers, and executives across the organization.

This integrated approach is the core philosophy behind platforms like Genspark. By providing a unified environment for research, analysis, and optimization, Genspark acts as a force multiplier, turning data into a strategic asset and enabling a truly intelligent, resilient, and responsive supply chain. It is the practical embodiment of the AI revolution, designed to solve today’s problems and prepare you for tomorrow’s.

Ready to Transform Your Supply Chain?

Discover how an all-in-one AI workspace can provide the clarity and control you need to navigate the complexities of 2025. Explore the future of supply chain management today.

Chapter 3: Core Capabilities: How an AI Workspace Optimizes Supply Chain Functions

An all-in-one AI workspace isn’t just a dashboard; it’s an active participant in your operations. By integrating various AI technologies, it fundamentally transforms core supply chain functions from reactive, manual processes into proactive, automated, and intelligent systems. Let’s break down how this works in practice.

3.1 Intelligent Demand Forecasting & Planning

The Problem: The High Cost of Guesswork

Traditional forecasting often relies on historical sales data, a method that is notoriously unreliable in today’s volatile market. Inaccurate forecasts lead to two costly outcomes: overstocking, which ties up capital and increases holding costs, or understocking (stockouts), which results in lost sales and frustrated customers. Luxury fashion brands, for example, have reported billions in excess inventory due to poor demand forecasting.

The AI Workspace Solution: Predictive Accuracy

An AI workspace revolutionizes forecasting by employing machine learning algorithms to analyze a much broader and more dynamic range of data. Instead of just looking at past sales, it can process:

- Real-time sales data from every channel.

- Market trends and competitor pricing scraped from the web.

- Social media sentiment and influencer activity that might signal a sudden surge in demand.

- Economic indicators, weather patterns, and local eventsthat could impact purchasing behavior.

By identifying complex correlations within this data, the AI can generate demand forecasts with a significantly higher degree of accuracy—some case studies show improvements of over 20%. This allows for precise supply chain planning, ensuring that the right products are in the right place at the right time. Studies have shown that AI implementation can lead to a 35% reduction in inventory levels and a 15% decrease in logistics costs.

3.2 Dynamic Inventory Optimization

The Problem: Balancing “Just-in-Time” with “Just-in-Case”

The classic inventory dilemma has been amplified by recent disruptions. While “just-in-time” (JIT) models are efficient, they are brittle and vulnerable to delays. This led many companies to pivot to “just-in-case” (JIC) strategies, piling up safety stock. However, JIC is expensive and inefficient. The ideal solution is a dynamic model that can adapt to real-time conditions.

The AI Workspace Solution: Real-Time Visibility and Control

An AI workspace provides the end-to-end visibility needed for truly dynamic inventory management. It achieves this through:

- Real-Time Inventory Tracking: By integrating with IoT sensors in warehouses and on transport vehicles, the platform provides a live, accurate count of all inventory, whether it’s on a shelf, on a truck, or on a ship. A recent survey found that 45% of supply chain executives consider a lack of real-time visibility a “significant issue.”

- Predictive Replenishment: The AI doesn’t just track current levels; it uses demand forecasts to predict when stock will run low and automatically triggers replenishment orders to prevent stockouts.

- Optimized Stock Placement: The system can analyze sales data by region to recommend the optimal distribution of inventory across multiple warehouses, minimizing shipping times and costs.

This level of control allows businesses to operate with leaner inventory levels without sacrificing resilience, striking the perfect balance between efficiency and security.

3.3 Proactive Risk Management and Resilience

The Problem: Reacting to Disasters

Too often, supply chain risk management is a reactive exercise. A company only realizes a supplier is in financial trouble when an order is missed, or a shipping lane is blocked when a vessel is already delayed. This firefighting approach is costly and disruptive.

The AI Workspace Solution: Sensing and Simulating Risk

An intelligent workspace shifts the paradigm from reaction to proaction. It acts as a 24/7 risk monitoring and mitigation engine by:

- Continuous Monitoring: The AI constantly scans global news, financial reports, weather alerts, and social media for any event that could impact the supply chain—from a factory fire at a tier-2 supplier to political unrest in a key shipping region.

- Supplier Risk Scoring: It can assess the health of every supplier in the network by analyzing their financial stability, operational performance, and compliance records, flagging high-risk partners before they cause a problem.

- Disruption Simulation: Using a concept known as a Digital Twin (which we’ll explore further in Chapter 4), the platform can simulate the impact of potential disruptions. What happens if a key port closes for a week? What if a primary supplier goes offline? The AI can run these scenarios and recommend contingency plans, such as activating alternate suppliers or rerouting shipments.

This capability allows businesses to build a truly anti-fragile supply chain—one that not only withstands shocks but can adapt and even grow stronger from them.

3.4 Smart Logistics and Warehouse Automation

The Problem: The Inefficient Last Mile

Logistics and warehouse operations are often rife with inefficiencies. Manual route planning doesn’t account for real-time traffic, leading to delays and wasted fuel. Inside the warehouse, manual picking and packing are slow, labor-intensive, and prone to error.

The AI Workspace Solution: End-to-End Automation

An AI workspace integrates intelligence from the warehouse floor to the customer’s door:

- Optimized Route Planning: AI-powered logistics tools analyze real-time traffic, weather data, fuel prices, and delivery windows to calculate the most efficient routes for every vehicle, every day. One U.S. retail chain using this technology cut delivery times by 18% and saved over $200,000 annually.

- Automated Warehouse Operations: The platform can orchestrate a fleet of autonomous mobile robots (AMRs) for picking and sorting. It uses computer vision to instantly identify products and check for quality defects, and machine learning to prioritize orders based on delivery deadlines. U.S. distribution companies have reported a 30-50% increase in warehouse throughput after integrating AI and robotics.

By automating these critical functions, the AI workspace dramatically increases speed and accuracy while reducing operational costs.

Chapter 4: Advanced Applications: Generative AI and Digital Twins

Beyond optimizing existing processes, an all-in-one AI workspace unlocks next-generation capabilities that were once the domain of science fiction. Two of the most powerful of these are Generative AI and Digital Twins. These technologies don’t just analyze data—they create, simulate, and strategize, acting as a true co-pilot for supply chain leaders.

4.1 Unleashing Generative AI: The Creative Strategist

While traditional AI is excellent at analyzing existing data to find patterns (analytical AI), Generative AI (GenAI) is designed to create new, original content. It’s the technology behind advanced chatbots and image generators, but its applications in supply chain are far more profound. Instead of just presenting a dashboard of numbers, GenAI can interpret that data and communicate it in a human-like way.

In an AI workspace, GenAI can:

- Synthesize Complex Reports: A manager can ask, “Summarize the key risks in our Southeast Asia supply chain for the next quarter and suggest three mitigation strategies.” The GenAI can analyze thousands of data points and generate a concise, actionable memo in seconds.

- Automate Supplier Communication: It can draft emails to suppliers to inquire about order status, negotiate terms, or even generate initial contract drafts based on predefined templates, which can then be reviewed by a human. This drastically reduces the administrative burden on procurement teams.

- Enhance Product Design: By analyzing data on material costs, manufacturing constraints, and customer feedback, GenAI can suggest modifications to product designs that would make them cheaper to produce or more durable, without sacrificing quality.

- Streamline Onboarding: For new suppliers, GenAI can power intelligent chatbots that guide them through the onboarding process 24/7, answering questions and validating documents in real-time, reducing onboarding timelines by as much as 70%.

Generative AI transforms the user’s interaction with the system from one of data extraction to one of conversation and collaboration. It makes the immense power of the underlying data accessible to everyone, regardless of their technical expertise.

4.2 The Power of the Digital Twin: The Virtual Sandbox

A Supply Chain Digital Twin is one of the most powerful strategic tools enabled by an AI workspace. It is a living, virtual simulation model of your entire physical supply chain. It’s not a static flowchart; it’s a dynamic replica that is continuously updated with real-time data from your ERP, warehouse management systems, IoT sensors, and logistics partners.

This virtual sandbox allows you to see the present and test the future with zero real-world risk. Key applications include:

- Strategic “What-If” Analysis: Before making a multi-million dollar decision, you can test it in the digital twin. What would be the cost and service impact of opening a new distribution center in Texas? How would shifting from air freight to ocean freight for a particular product line affect inventory levels and lead times? The digital twin provides data-backed answers.

- Bottleneck Discovery: By visualizing the end-to-end flow of goods, the digital twin can pinpoint hidden bottlenecks that cause cascading delays. It might reveal that a specific customs checkpoint is consistently slow or that a particular warehouse’s layout is inefficient during peak hours.

- Resilience Testing: As mentioned in the previous chapter, the digital twin is the ultimate tool for risk management. You can simulate a wide range of disruptions—a supplier bankruptcy, a natural disaster, a sudden 50% spike in demand—and see exactly how your supply chain would respond. This allows you to develop and validate contingency plans before a crisis hits.

- Operational Forecasting: The digital twin can be used to forecast operations over the coming days and weeks. By feeding it with current orders and logistics data, it can predict potential delays and capacity constraints, allowing managers to intervene proactively.

A digital twin, powered by an integrated AI workspace, moves a company from managing its supply chain to orchestrating it. It provides a level of foresight and control that was previously unimaginable, de-risking major transformations and optimizing both long-term strategy and day-to-day operations.

Chapter 5: Democratizing Data: The AI Workspace for Every Stakeholder

One of the most profound impacts of an all-in-one AI workspace is its ability to break down the walls that have traditionally separated different parts of an organization. Supply chain management is not just a logistics function; it is deeply intertwined with finance, marketing, sales, and customer service. A truly effective solution must serve all these stakeholders, democratizing access to data and fostering collaboration.

5.1 Breaking Down Information Silos

In many companies, supply chain data is fragmented across dozens of disconnected systems: the ERP holds financial data, the WMS holds warehouse data, the TMS holds transport data, and spreadsheets hold everything in between. This “supply chain fragmentation” creates information silos, leading to:

- Inefficiency and Delays: As information is manually passed between departments, errors are introduced and decisions are slowed down.

- Lack of a Single Source of Truth: The marketing team might be planning a promotion based on one set of inventory numbers, while the logistics team is working with another. This leads to misaligned strategies and poor outcomes.

- Hidden Inefficiencies: Without an end-to-end view, it’s impossible to see how a decision in one department impacts another.

An integrated AI workspace solves this by creating a unified data layer, or a “single source of truth.” It pulls data from all these disparate systems into one central hub. This ensures that everyone—from procurement to finance to customer service—is looking at the same real-time information. This seamless data sharing enables true cross-functional collaboration and allows the organization to operate as a single, cohesive unit.

5.2 Empowering Small and Medium-Sized Enterprises (SMEs)

Historically, sophisticated supply chain management technology has been the exclusive domain of large enterprises with deep pockets and large IT departments. SMEs have been left to struggle with spreadsheets and basic software, facing immense challenges in several areas:

- Budget Constraints: Inability to afford expensive, monolithic software suites.

- Data Quality: Difficulty maintaining accurate and consistent data across manual systems.

- Limited Visibility: A lack of tools to see what’s happening across their supply chain, making it hard to manage risks and costs.

- Scalability Issues: As the business grows, their manual systems quickly become overwhelmed, hindering expansion.

A cloud-based, all-in-one AI workspace levels the playing field. Because it is typically offered as a Software-as-a-Service (SaaS) model, it eliminates the need for massive upfront investment in hardware and software. SMEs can access enterprise-grade capabilities—like predictive analytics, automation, and real-time tracking—on a subscription basis. This provides them with the scalability to grow and the flexibility to adapt to market changes, allowing them to compete with much larger players on a more equal footing.

5.3 Enhancing the Customer Experience

Ultimately, the goal of any supply chain is to serve the customer. A disconnected and inefficient supply chain inevitably leads to a poor customer experience. An AI workspace directly enhances customer satisfaction by enabling:

- Accurate Promises: By having real-time visibility into inventory and production schedules, the sales team can make accurate delivery promises to customers.

- Proactive Communication: If the AI predicts a potential delay, the system can automatically notify the customer and provide a revised delivery estimate, turning a negative experience into a positive, transparent interaction.

- Seamless Order Tracking: The platform can provide customers with a single, easy-to-use portal to track their order’s journey from the moment it’s placed to the moment it arrives.

- Intelligence from Customer Interactions: Data from customer service chatbots and emails can be fed back into the AI workspace. This provides a rich source of intelligence on product issues, changing preferences, and future needs, creating a virtuous cycle of improvement.

By connecting the back-end operations of the supply chain directly to the front-end customer experience, the AI workspace ensures that the entire organization is aligned around its most important goal: creating happy, loyal customers.

The Collaborative Advantage: An all-in-one AI workspace is more than a tool; it’s a new way of working. It fosters a culture of transparency, collaboration, and data-driven decision-making that empowers every employee and strengthens every partnership, from the smallest supplier to the largest customer.

Chapter 6: Getting Started with Your AI-Powered Supply Chain Transformation

The journey toward an intelligent supply chain can seem daunting, but the tools and strategies to begin are more accessible than ever. The evidence is clear: the risks of inaction far outweigh the challenges of adoption. Embracing this transformation is not merely about implementing new technology; it’s about adopting a new mindset focused on agility, data, and continuous improvement.

A Shift in Mindset, A Leap in Capability

The first step is recognizing that the old ways of working are no longer sufficient. Leaders must champion a culture that:

- Values Data as a Strategic Asset: Every decision, from sourcing to delivery, should be informed by data and analytics.

- Embraces Agility: The ability to respond quickly to market shifts and disruptions is a key competitive advantage.

- Fosters Digital Curiosity: Professionals at all levels should be encouraged to learn and leverage new AI tools to enhance their roles, not fear them. AI is not here to replace supply chain professionals, but to augment their intelligence and free them from manual tasks to focus on strategy and innovation.

The Solution is Here: Your Central Intelligence Hub

You don’t need to build a complex AI ecosystem from scratch. The most effective and efficient way to begin your transformation is by adopting an all-in-one AI workspace. A platform like Genspark provides the foundational layer for your intelligent supply chain, integrating your existing systems and immediately unlocking powerful capabilities.

It serves as your central hub for research, analysis, and optimization, providing the end-to-end visibility and predictive insights needed to navigate the complexities of the modern world. It is a practical, scalable, and powerful first step toward building a supply chain that is not just resilient, but truly intelligent.

Take Control of Your Supply Chain’s Future

The era of reactive, fragmented supply chain management is over. The future is integrated, intelligent, and predictive. Don’t let complexity dictate your success. Take the first step towards transforming your operations and gaining a decisive competitive edge.

Explore how the Genspark all-in-one AI workspace can become the central nervous system for your supply chain.

Comments